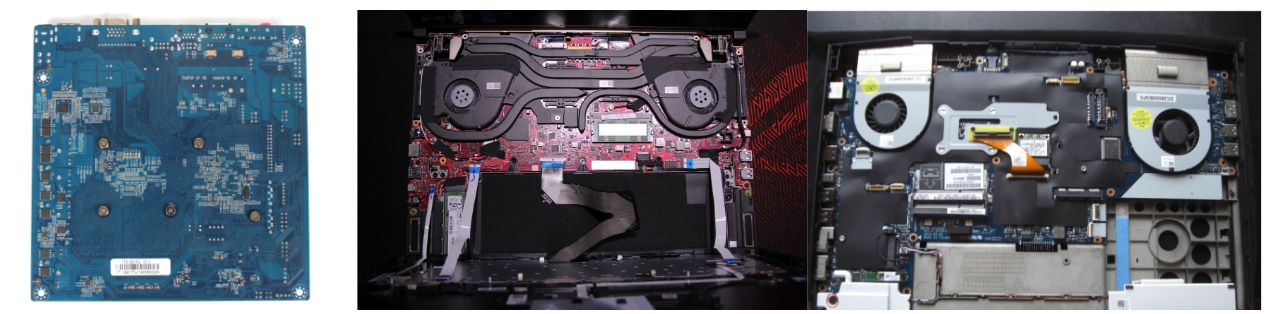

3C digital communication base station (notebook computer, tablet computer,) calculator, camera lens learning machine, home appliance, toy new energy, aerospace and military industry

In the manufacture of products, lock screw as a very important part of the fastening process! At present, the products are constantly updated and have very high requirements on the fastening method of the lock screw, the locking torque and the material of the products. Our company has also provided reliable and stable solutions to common problems in daily production, such as tooth sliding, floating height, flying screws, stuck screws, locked products and other defective rate problems.

Main functions:

Motion card control system · CCD visual positioning · lock screw control system (optional)

CCD auxiliary teaching screw coordinate point, CCD intelligent screening bad screw hole, screw floating height displacement sensor, automatic learning coordinate height; (Visual Positioning System Function)

Support laser displacement sensor floating height detection module, support leakage lock, sliding lock and floating height detection and verticality automatic detection device Before the machine goes online, the matching angle of the batch head/suction nozzle is absolutely guaranteed; (Visual Positioning System Function)

Real-time monitoring of torque, speed, and other information, and tightening judgment;

Supports MES data upload.

Electrical characteristics

Brushless electric batch, carbon brush electric batch, intelligent electric batch: any torque, speed setting, output torque waveform and torque value; (optional)

Locking efficiency: 2.0~2 5S/piece, depending on screw specifications

Programming mode

Handle alignment · CCD coordinate teaching CAD coordinate import teaching 15 inch LCD keyboard mouse (optional)